What is Quality Management and what are the different components? What is the difference between Quality Management, Quality Assurance, Quality Control, or Quality Engineering? And do Quality Planning and Quality Improvement fit into that picture?

Unfortunately, different websites come with different definitions, some of them even contradicting. But here is mine.

Quality Management ensures consistency of processes, as well as products and services.

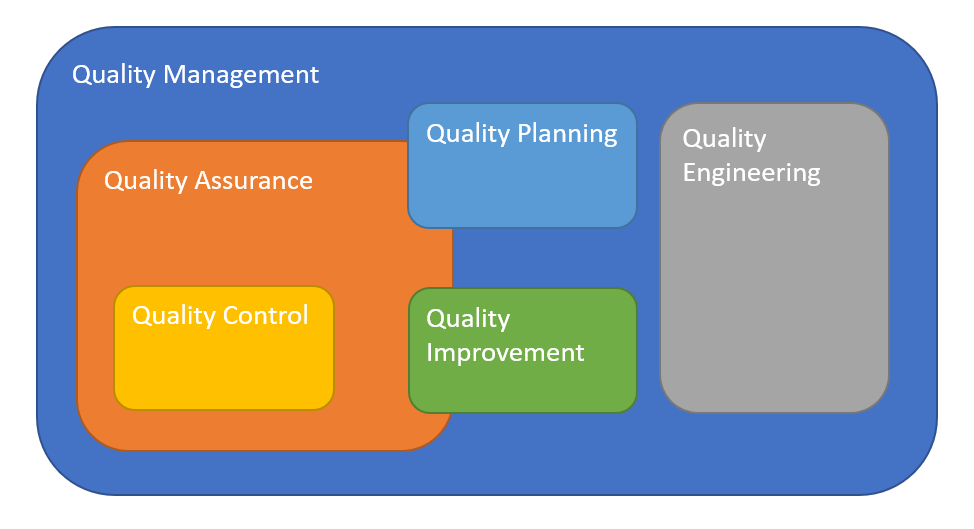

And there are 5 components involved as shown in the following picture

Quality Planning

Quality Planning (QP) is a process, primarily to identify the relevant quality standards of a project or product and subsequently the decision on how to meet those standards.

This is basically about two things: (1) finding out which quality requirements are relevant for my product or service and (2) what I need to do to meet those requirements.

Example: Let’s use a car factory as an example. There are tons of regulations in the automotive industry, but one quality requirement could be: The car needs to have 4 wheels, leading to the Quality requirement: exactly 4 wheels, attached to the car in a way that they can roll, one at every corner, all rolling into the same direction.

And what do we need to do to meet this requirement? Provide 4 wheels for each car at the assembly line and provide good work instructions on how to attach them.

Quality Control

Quality Control (QC) is the continuous effort to keep the integrity and reliability of a process to achieve the desired outcome.

This is primarily about checking if the desired outcome is really happening. If not, we can correct the outcome to make sure that the outcome of the process stays reliable.

Example: Coming back to our car example, it is nice that we defined the 4-wheel requirement and we provided the wheels to the assembly line and we provided detailed instructions on what to do with those wheels. But can we be sure that each car will end up with 4 wheels as specified? Probably not. Imagine one of the assembly workers had a bad day and his mind is somewhere else and he simply forgets to attach one of the wheels. We all have bad days sometimes and sh… happens. So we better establish a checkpoint, which checks the car before delivery if there are really 4 wheels attached as specified. If not, we have a chance now to correct that mistake before we deliver that car to a customer.

Quality Assurance

Quality Assurance (QA) is the sum of all planned and systematic actions necessary to provide sufficient reliability so that a service or product will meet the specified requirements.

In short, do all you can to make your product a good one. So everything done under Quality Control fits that definition, hence QC is a subset of QA. But what else is part of QA? Imagine your QC is quite good and you find and correct many issues. So far so good for defect identification, but you grow tired of being so reactive and you would like to avoid those issues coming into your product in the first place.

That’s where the second part of QA comes into the picture. Defect prevention means avoiding that issues have to be found and corrected later on. The solution is simple: Find issues early and fix them early and if possible, don’t introduce them at all. And there are many ways to do that.

Example: Again our car example. What if the assembly line worker would not be able to move to the next car until all 4 wheels are attached? What if the next 4 wheels for the next car wouldn’t be available until the previous car has all 4 wheels attached properly? This way it would be impossible to end up with a 3-wheel car later on in the QC phase. This way we would prevent the 3-wheels-only-issue.

Quality Improvement

Quality Improvement is the intentional and purposeful change of processes in order to improve the confidence or reliability of the outcome of those processes.

If things are going well, don’t stop improving. If you settle for good, you’ll never be excellent and there is always something, which can be improved to become more effective, more efficient, and more productive.

Example: You made sure that the four wheels are mounted to each car successfully and without any quality issues later on. You could be okay with that state of your process. or could analyze if there is more to improve. E.g. you could reduce the time to mount all 4 wheels from 5 minutes to 4 minutes, just by placing the 4 wheels and corresponding tools in a more efficient way before you start.

Quality Engineering

Quality Engineering (QE) is the management, development, operation, and maintenance of IT systems and enterprise architectures with a high-quality standard.

What does this mean? It means basically that you need proper IT systems to be successful on your quality journey. For example, a proper build system helps you to build faster and to detect build issues earlier. Or an artifact repository helps you reduce build times by storing unchanged binaries to be reused. Or a proper CI setup will help you to avoid somebody merging faulty code into your master branch.

In short, the proper tooling setup will save your ass multiple times.

Example: Your car production assembly line is running fine if there weren’t those unnecessary pauses when the to-be-mounted wheels are not in time at the assembly station in case the wheel stock runs low. A proper software, which displays the number of wheels in stock and reorders wheels when running low soon, will help you to avoid those pauses.

Join our newsletter and become a part of our ‘Quality Management Club’, to not miss future blog posts.